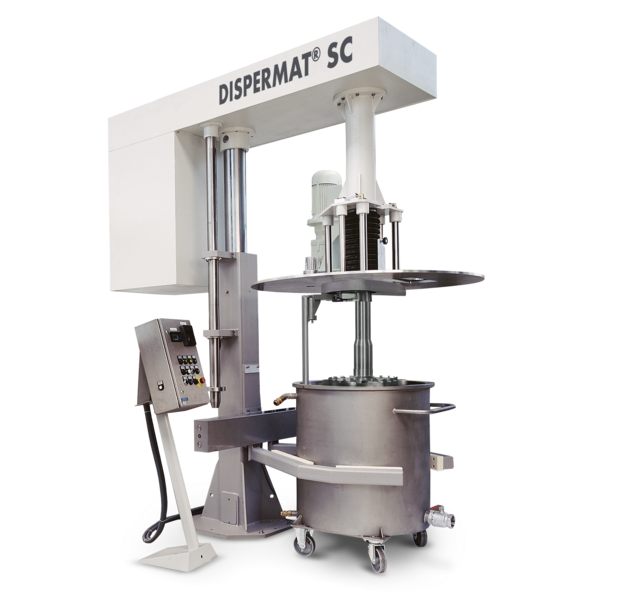

DISPERMAT® SCA6-EX dissolver

Explosion-proof production disperser for containers up to 2500 liters with a scraper system

- Power

- 45 – 55 kW

- Product

- 400 – 2000 litres

- Control

- C / SC / PLC

The DISPERMAT® SCA6-EX disperser is a multipurpose production dissolver for product quantities from 400 to 2000 liters. The dissolver is available for container sizes of up to 2500 liters. According to the more

Description

Explosion-proof DISPERMAT® SCA6-EX production dissolver with a scraper

The DISPERMAT® SCA6-EX disperser is a multipurpose production dissolver for product quantities from 400 to 2000 liters. The dissolver is available for container sizes of up to 2500 liters. According to the Directive 2014/34/EU (ATEX 100a), the explosion-proof production dissolver corresponds to the following ATEX protection class: II 2G Ex h IIB T3 Gb.

The explosion-proof DISPERMAT® SCA6-EX production dissolver has an especially powerful scraper system:

In order to guarantee a perfect dispersion or grinding process even with very high viscosity and non-flowing substances, very often a scraper system is absolutely essential. The integrated spring pressure presses the scraper arm against the inner wall of the container and therefore ensures that the product is reliably conveyed over and over again towards the container center. The exchangeable scraper arms enable the flexible use for different container sizes.

The explosion-proof DISPERMAT® SCA6-EX production disperser has an integrated cover:

The stable cover of the DISPERMAT® SCA6-EX enables easy height adjustment of the shaft even during dispersion. The cover rests securely on the container edge during dispersion. The cover is equipped with a product feed system as a standard. Various options, such as LED lighting, a PT100 temperature sensor, a Liquiphant level switch (also in ATEX), or sight glasses and various filling funnels are available for the container cover.

The DISPERMAT® SCA6-EX production dissolver is equipped with a T6 hydraulic stand:

The T6 stand of the DISPERMAT® SCA6-EX is a tried and tested hydraulic stand for product quantities of up to 2,000 liters. The height is adjusted hydraulically via a system on the stand base.

The applications of our high quality DISPERMAT® SCA6-EX disperser are versatile:

- Paints and varnishes

- Pigments and additives

- Printing inks

- Chemistry

- Plastics

- Construction chemistry

- Electronics

- Adhesives

- Coatings

- Pharmacy and cosmetics

- Microbiology

- Agrochemicals

- Ceramics, etc.

Highlights DISPERMAT® SCA6-EX dissolver

<p>ZONE 0/1/2<br /> explosion protection</p>

<p>SCRAPING SYSTEM<br /> for highly viscous products</p>

<p>HYDRAULIC<br /> robust hydraulic stand</p>

<p>DIRECTIVE 2006/42/EC<br /> integrated safety equipment</p>

<p>PROCESS CONTROL<br /> repeatable dispersion results</p>

<p>SPEED ADJUSTMENT<br /> with rotary pulse encoder</p>

<p>TÜV CERTIFIED<br /> Safety module (EN ISO 13849-1)</p>

<p>SOFTWARE<br /> documentation, research and QA</p>

<p>DISPERMAT® TECHNOLOGY<br /> dispersing highly viscous substances</p>

<p>SINCE 1972<br /> quality, precision & durable technology</p>

Features

| DISPERMAT® | Power | Speed | Torque | Product | Container |

|---|---|---|---|---|---|

| DISPERMAT® SCA6-45 EX Dissolver | 45 kW | 100 - 985 rpm | 876 Nw | 400 - 2000 liters 105 – 530 gallons | 500 - 2500 liters 132 – 660 gallons |

| DISPERMAT® SCA6-55 EX Dissolver | 55 kW | 100 - 985 rpm | 1069 Nw | 400 - 2000 liters 105 – 530 gallons | 500 - 2500 liters 132 – 660 gallons |

| Category 1 | Category 2 | Category 3 | |

|---|---|---|---|

| Hazard | permanent, frequent or over an extended time | occasionally | rarely and for a short time |

| Requirement | very high safety | high safety | normal safety |

| Zone / Substance group | Zone 0 / Gas Zone 20 / Dust | Zone 1 / Gas Zone 21 / Dust | Zone 2 / Gas Zone 22 / Dust |

Temperature classes and explosion groups

Refer to temperature classes and explosion groups for an assignment of gases and vapours.

| Explosion group | T1 >450°C | T2 300 ‒ 450°C | T3 200 ‒ 300°C | T4 135 ‒ 200°C | T5 100 ‒ 135°C | T6 85 ‒ 100°C |

|---|---|---|---|---|---|---|

| IIA | acetone ethane ammonium benzol acetic acid carbon oxide methane methanol methyl chloride naphthalene phenol propane toluene | i-amyl acetate n-butane n-butyl alcohol cyclohexanol 1,2 -dichloroethane acetic anhydride | benzines diesel kerosene fuel oils n-hexane | acetaldehyde | ||

| IIB | city gas | ethylene | hydrogen sulphide | ethyl ether | ||

| IIC | hydrogen | acetylene | carbon disulphide |

Process control

The DISPERMAT® SCA6-EX production dissolver can be equipped with various control technologies.

C technology

DISPERWHEEL® speed adjustment

infinitely variable speed adjustment with rotary pulse encoder

Large color display

indications of speed, torque, power, product temperature, timer, peripheral speed and height of the dispersing tool

Repeatability

dispersion method: constant speed or constant mechanical power input for optimum repeatability, temperature‒based dispersing

Data recording

recording of the process parameters with graphical indication

Switch off parameters

switch off function for temperature, speed, torque and power

Database

100 individual PRESET configurations for H1, H2, speed, time, switch off parameters, ramp function, etc.

DISPERSAFE®

TÜV-certified safety module for convenient use of variable container sizes without limit switches or mechanical contraption. more …

Power compensation

net power calibration

Height measurement

adjustable working range for different container sizes

Connectivity

USB

WINDISP 7©

data interface for WINDISP© 7 software for documentation, analysis, research, development and quality control

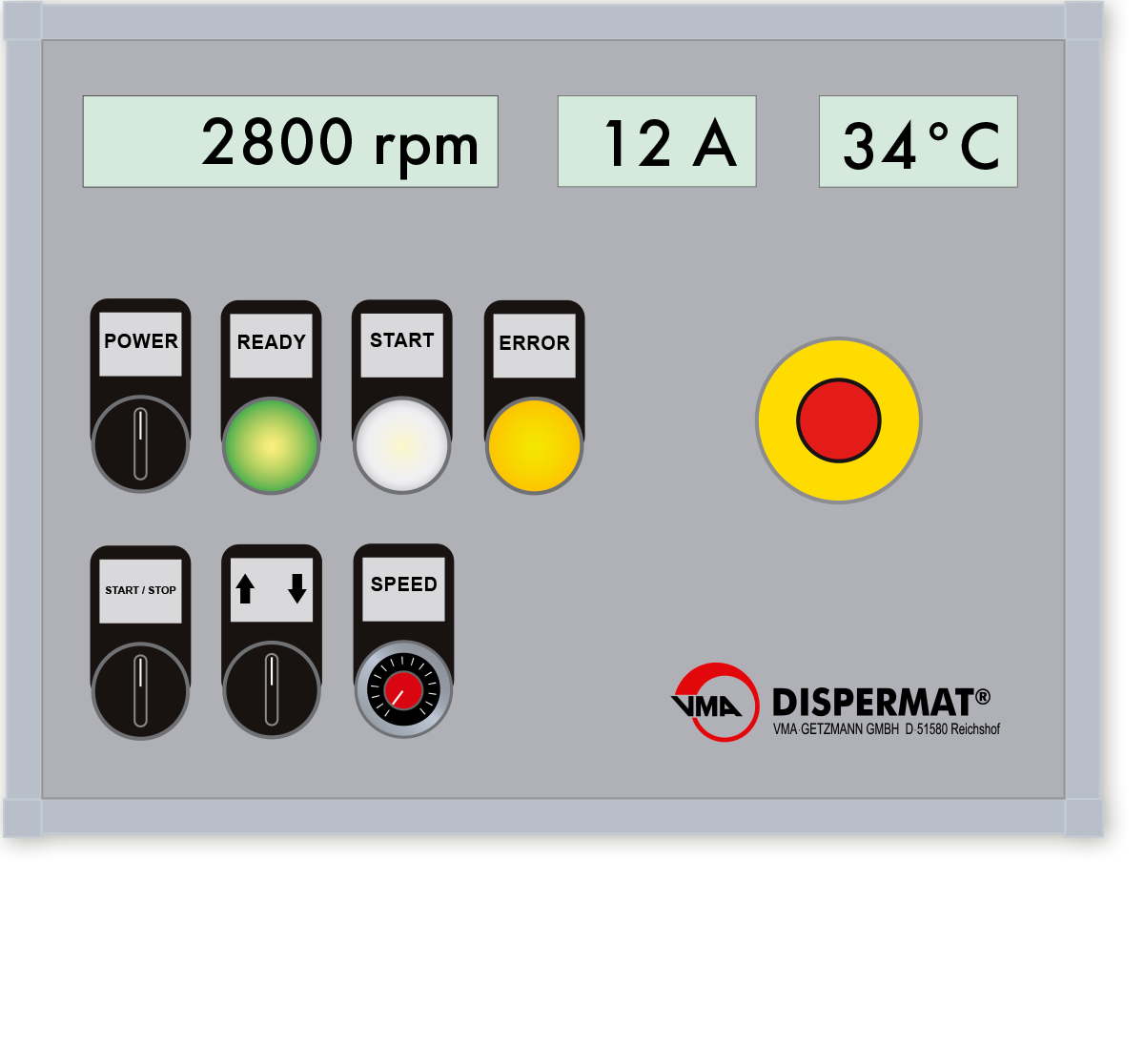

SC technology

Speed adjustment:

infinitely variable speed adjustment

Digital indication:

for speed, ampere and product temperature (as an option)

Height adjustment:

convenient height adjustment for the drive motor

Operator controls for:

power, start, stop and emergency stop

PLC technology

The DISPERMAT® and TORUSMILL® dissolvers, bead mills and basket mills can also be fitted with the PLC-control. The graphic display allows for an indication of the operational parameters such as speed, power output, peripheral speed of the milling tool, torque and product temperature. The combination of a graphic display and the standardized PLC-control allows for an extension as well as for an adaptation of the control system to further process control applications at any time.