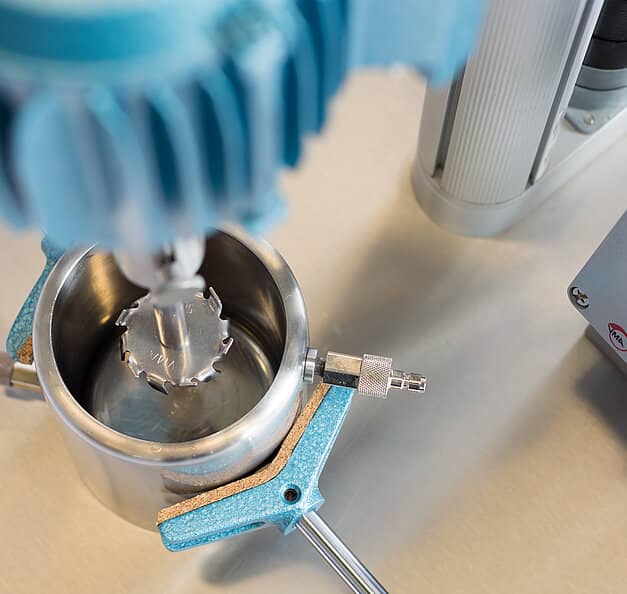

DISPERMAT® LC-EX dissolver

Explosion‒proof laboratory dispersers for zone 2 with electric height adjustment

- Power

- 0.25 - 0.75 kW

- Product

- 0.05 - 10 litres

- Control

- LC-EX [Basic]

Description

Convenient dissolver for stirring, dispersing, dispersion under vacuum, homogenizing and fine grinding in hazardous areas of zone 2.

The DISPERMAT® LC-EX dispersers are designed specifically for laboratory dispersion work in hazardous areas where ATEX approved machines are required. The new competitive DISPERMAT® LC-EX models are explosion‒proof laboratory dissolvers according to explosion class Zone 2, Category 3G IIB T3. The instruments have integrated control panels and contain all essential explosion‒proof controls for easy operation of the unit: ON/OFF switch, potentiometer for an infinitely speed adjustment and a switch for operating the electric height adjustment. Due to the integrated explosion‒proof safety device consisting of the container clamping system (LC25-EX: container clamping system), the working height monitoring of the dispersion tool and the shaft protection pipe, a safe and comfortable work with the laboratory dissolvers DISPERMAT® LC25-EX, LC55-EX and LC-75-EX is assured. The separate control cabinet with the power electronics is situated outside the hazardous area.

Highlights DISPERMAT® LC-EX dissolver

<p>MODULAR SYSTEMS<br /> Flexible. Powerful. Innovative.</p>

<p>ZONE 0/1/2<br /> explosion protection</p>

<p>ELECTRIC<br /> easy handling, functional design</p>

<p>DIRECTIVE 2006/42/EC<br /> integrated safety equipment</p>

<p>SINCE 1972<br /> quality, precision & durable technology</p>

Features

| DISPERMAT® type | low‒viscosity up to 500 mPs | medium‒viscosity 500 ‒ 5000 mPs | high‒viscosity over 5000 mPs |

|---|---|---|---|

| Dissolver DISPERMAT® LC25-EX | 0.05 – 3 liters 1.7 oz – 3.2 qt | 0.05 – 1.5 liters 1.7 oz – 1.6 qt | 0.05 – 1 liters 1.7 oz – 1.1 qt |

| Dissolver DISPERMAT® LC55-EX | 0.25 – 5 liters 8.5 oz – 1.3 gallons | 0.25 – 3 liters 8.5 oz – 3.2 qt | 0.25 – 1.5 liters 8.5 oz – 1.6 qt |

| Dissolver DISPERMAT® LC75-EX | 0.25 – 10 liters 8.5 oz – 2.6 gallons | 0.25 – 5 liters 8.5 oz – 1.3 gallons | 0.25 – 2.5 liters 8.5 oz – 2.6 qt |

| DISPERMAT® LC25-EX Stand H1B | DISPERMAT® LC55-EX - LC75-EX Stand H2BT | |

|---|---|---|

| Dimensions W x H x D | 70 x 84 x 48 cm 28 x 33 x 19 inch | 73 x 121 x 61 cm 29 x 48 x 24 inch |

| Height adjustment | mechanical | electric |

| Container capacity | 0.125 - 10 litres 4.2 oz – 2.6 gallons | 0.5 - 20 litres 16.9 oz – 5.3 gallons |

| Container clamping range Ø | 3 - 34 cm 1.2 ‒ 13.4 inch | 5 - 35 cm 2 ‒ 13.8 inch |

| Container height | 10 - 35 cm 3.9 ‒ 13.8 inch | 7 - 38 cm 2.8 ‒ 15 inch |

| Container clamping system | clamping device | central container clamping device |

| Safety device | no | yes |

| Weight | 40 kg 88 lbs | 90 kg 198 lbs |

| Category 1 | Category 2 | Category 3 | |

|---|---|---|---|

| Hazard | permanent, frequent or over an extended time | occasionally | rarely and for a short time |

| Requirement | very high safety | high safety | normal safety |

| Zone / Substance group | Zone 0 / Gas Zone 20 / Dust | Zone 1 / Gas Zone 21 / Dust | Zone 2 / Gas Zone 22 / Dust |

Temperature classes and explosion groups

Refer to temperature classes and explosion groups for an assignment of gases and vapours.

| Explosion group | T1 >450°C | T2 300 ‒ 450°C | T3 200 ‒ 300°C | T4 135 ‒ 200°C | T5 100 ‒ 135°C | T6 85 ‒ 100°C |

|---|---|---|---|---|---|---|

| IIA | acetone ethane ammonium benzol acetic acid carbon oxide methane methanol methyl chloride naphthalene phenol propane toluene | i-amyl acetate n-butane n-butyl alcohol cyclohexanol 1,2 -dichloroethane acetic anhydride | benzines diesel kerosene fuel oils n-hexane | acetaldehyde | ||

| IIB | city gas | ethylene | hydrogen sulphide | ethyl ether | ||

| IIC | hydrogen | acetylene | carbon disulphide |

Process control

The explosion proof DISPERMAT® LC-EX dissolver is fitted with the LC-EX technology

LC-EX technology

Speed adjustment

infinitely variable speed adjustment

Electric height adjustment

Control of the convenient electrical height adjustment of the drive motor

ON/OFF switch

Emergency off switch

Adaptable systems

Flexible. Powerful. Innovative.

Innovation made in Germany: With the modular quick-change systems, the DISPERMAT® LC-EX dissolver can also be used as: APS Bead Mill, TORUSMILL® TML Basket Mill, CDS Vacuum Dispersion System and SR Rotor-Stator Homogenizer .

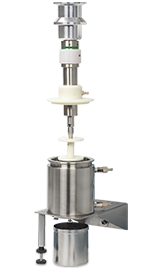

APS Bead Mill

Modular bead mill for DISPERMAT® dissolvers.

The addition of the modular APS bead mill converts the DISPERMAT® dissolver into a closed batch bead milling system.

APS Bead Mill

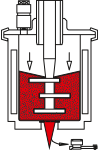

TORUSMILL® TML Basket Mill

Modular basket mill for DISPERMAT® dissolvers

The addition of the modular TML basket mill converts the DISPERMAT® dissolver into an extremely efficient fine grinding system.

TORUSMILL® TML Basket Mill

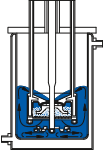

CDS Vacuum Dispersion System

Modular vacuum system for DISPERMAT® dissolvers

The CDS vacuum dispersion system enables the dispersion process in a completely closed system under vacuum.

CDS Vacuum Dispersion System

SR Rotor-Stator Homogenizer

Modular rotor-stator dispersion system

Vertical high-performance rotor-stator systems for homogenizing, emulsifying, dispersing, mixing and dissolving.

SR Rotor-Stator Homogenizer