Fabricación aditiva / Impresión 3D

3D printing is becoming increasingly popular not only in industry, but also in the private sector. Using this new technology, you can produce both prototypes and prefabricated components from a wide variety of materials. For plastic filaments and UV-curing resins, it is important to disperse and grind required pigments as finely as possible in order to achieve the greatest possible color strength. This is the only way to ensure that the color of plastic materials remain unchanged and evenly distributed after the melting process. This method also prevents 3D printing nozzles from being clogged.

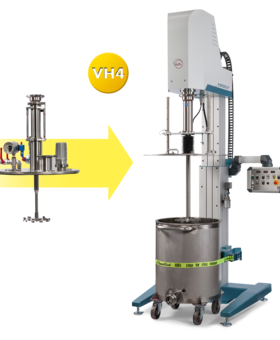

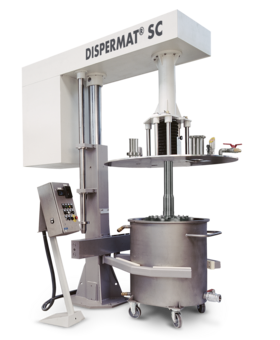

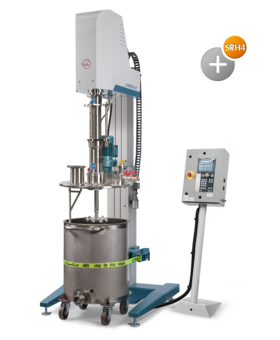

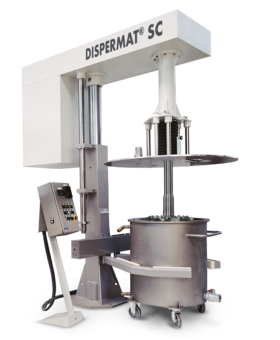

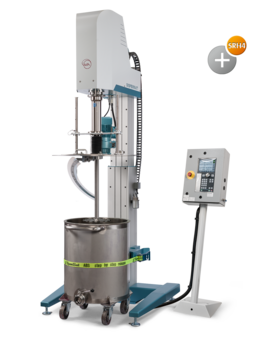

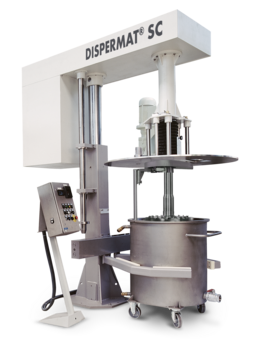

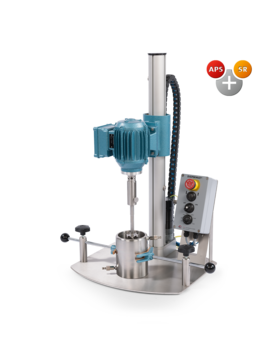

Our customers trust in the mature technology of our dispersion and grinding DISPERMAT® devices and use them successfully in their manufacturing process.