TORUSMILL® TML500/1000 basket mill

FLEXIBLE. POWERFUL. INNOVATIVE. Modular basket mill for DISPERMAT® production dissolvers

- Product

- 100 - 1000 litres

The addition of the modular basket mill TORUSMILL® TML500/1000 converts the DISPERMAT® SC5 and DISPERMAT® SC5-EX production dissolver into an extremely efficient grinding system. After the predispersion has more

Description

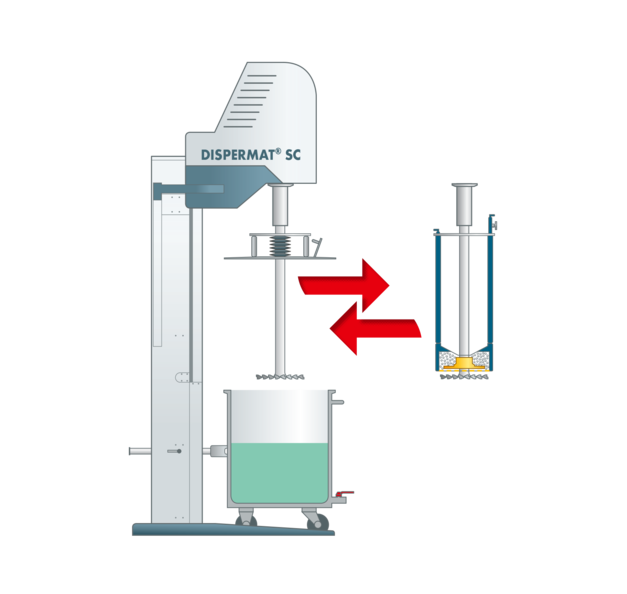

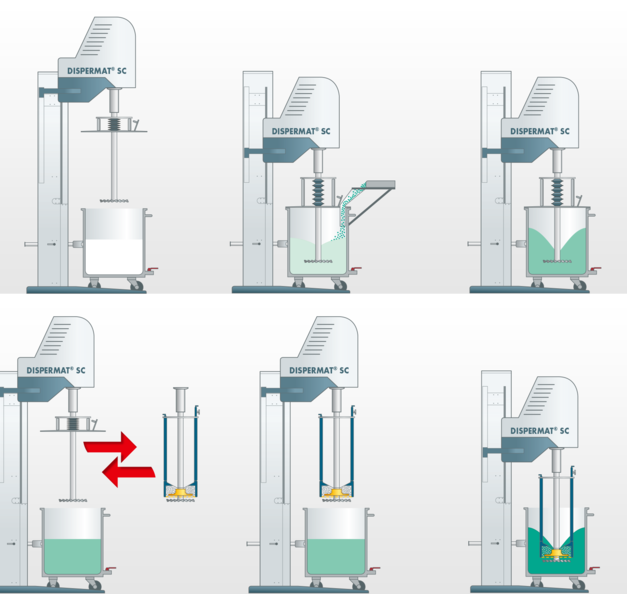

TORUSMILL® TML basket mill: extreme fast batch and system changes in production

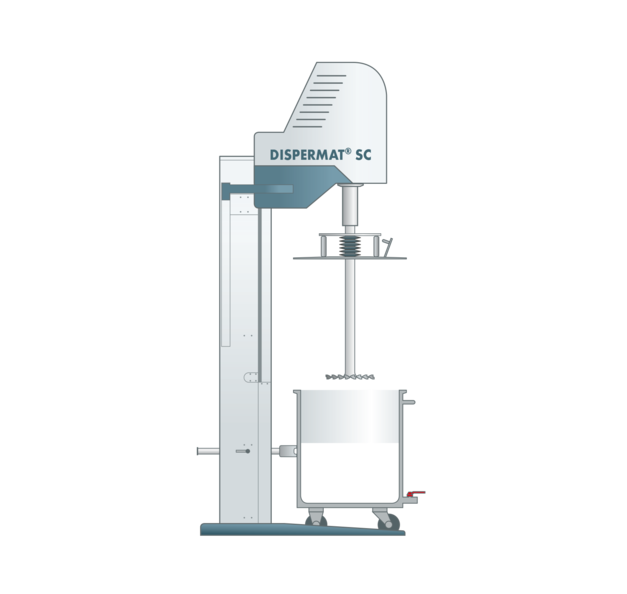

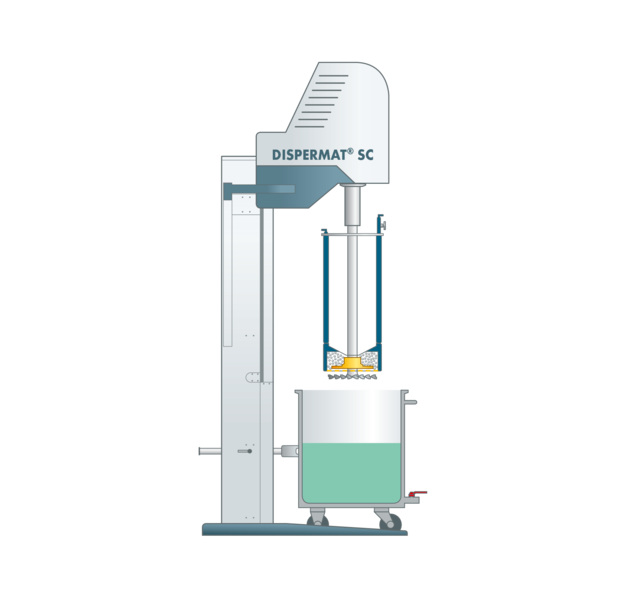

The addition of the modular basket mill TORUSMILL® TML500/1000 converts the DISPERMAT® SC5 and DISPERMAT® SC5-EX production dissolver into an extremely efficient grinding system. After the predispersion has been completed, only the dissolver disc is unscrewed and the TORUSMILL® TML grinding basket is coupled with our patented quick-change system. Immersion mills are highly efficient batch grinding systems comprising of a grinding basket that is lowered into the millbase for dispersion. During operation the grinding basket stands still while the milling shaft to which the milling tool, dissolver disc and pump wheel are fastened, rotates. The rotating milling tool agitates the beads inside the basket which disperses the millbase. The dissolver disc at the tip of the shaft and the pumping wheel generate effective circulation of the millbase, helping to provide excellent fine grinding results in a short period of time.

The milling basket is double‒walled for cooling and has a sieve that retains the milling beads but allows the millbase to pass through. The optimized design and the polished surfaces guarantee minimal dead areas and particularly easy and quick cleaning of the grinding basket.

Particularly environmentally friendly and efficient fine grinding technology

- excellent dispersion results in a short time

- excellent product circulation due to dissolver disc and pump wheel

- highly repeatable dispersion results

- uniform average residence time

- narrow particle size distribution

- no dead areas due to effective mill base circulation

- no escape of milling beads during the dispersion

- dispersion in a closed system

- low energy requirement

- Simple cleaning and quick change of millbase

- Especially user‒friendly milling system: very simple and safe handling

The TORUSMILL® TML basket mill is available in the following designs:

- TORUSMILL® TML basket mill

Standard design for using milling beads from 0.6 mm. Optional: vacuum and ceramic option

- TORUSMILL® TML-VACUUM basket mill

For dispersion under vacuum. Optional: ceramic option

- TORUSMILL® TML-CERAMIC basket mill

Milling chamber, milling disc, separation sieve and container can be supplied in SiSiC or ZrO2. Optional: vacuum option

Highlights TORUSMILL® TML500/1000 basket mill

<p>MILLING SYSTEM<br /> made of ZrO2 or SiSiC</p>

<p>DISPERMAT® TECHNOLOGY<br /> dispering under vacuum</p>

<p>ZONE 0/1/2<br /> explosion protection</p>

<p>SINCE 1972<br /> quality, precision & durable technology</p>

Features

| TORUSMILL® TML | Container capacity | Product volume | Milling chamber volume |

|---|---|---|---|

| TORUSMILL® TML500 basket mill | 200 - 1250 liters 53 – 330 gallons | 100 - 1000 liters 26 – 264 gallons | 15 liters 4 gallons |

| TORUSMILL® TML1000 basket mill | 200 - 1250 liters 53 – 330 gallons | 100 - 1000 liters 26 – 264 gallons | 25 liters 6.6 gallons |