DISPERMAT® SL-C bead mill

Laboratory and pilot plant horizontal bead mill for repeatable fine grinding

- Power

- 1.1 – 4 kW

- Product

- 0.05 – 50 litres

- Control

- C [Comfort]

DISPERMAT SL-C laboratory and pilot plant mills are closed, horizontal agitator ball mills with high output and extremely low dead volumes. During the dispersion process, the product is fed through the more

Description

Fine grinding with extensive process control

DISPERMAT SL-C laboratory and pilot plant mills are closed, horizontal agitator ball mills with high output and extremely low dead volumes. During the dispersion process, the product is fed through the horizontal milling chamber and continuously dispersed. The DISPERMAT® SL-C bead mill can be used for single pass as well as re‒circulation milling. After dispersion, the integrated air pressure system presses the remaining mill base out of the milling chamber which provides a complete recovery of the dispersed material.

Due to the low dead volume even the smallest quantities can be dispersed with high yield making the DISPERMAT® SL-C an ideal tool for research, development and quality control. Larger quantities can also be processed within a very short period of time. In order to minimise the product loss, the mill base is fed directly from the supply vessel into the milling chamber. The dispersed product passes through the mill base separation (dynamic gap) and is recovered either in a vessel (single pass) or flows back into the supply vessel (re‒circulation method).

- Quick and cost effective dispersion of new formulations due to exact repeatability of dispersions.

- Quick and reliable transfer of laboratory development into production because of quantitative knowledge of the required mechanical power input.

- Quality control and assurance of production.

The milling system is made of a special wear‒resistant, high alloy steel. As an option it is also available made of:

- Ceramic or hard metal is also available for pharmaceutical and electronic applications where metallic abrasion in the millbase has to be avoided.

- ZrO2 zirconium oxide: a hardwearing white ceramic for minimal wear or colour contamination.

- SiSiC silicon carbide: a hard black ceramic for minimal wear and with excellent heat transfer properties

The DISPERMAT® SL-C agitator ball mill is supplied with VITON (FKM‒rubber) O‒rings as standard. EPDM (ethylene propylene) O‒rings can be fitted at no extra charge. If VITON or EPDM is not compatible with the products being milled, perfluoroelastomeres O‒rings are recommended: KALREZ®, CHEMRAZ®, PERLAST®.

Special benefits of the DISPERMAT® SL-C bead mill

- Milling chamber of wear‒resistant high alloy stainless steel with hardened nitrided steel. The milling chamber and the milling rotor are available in hard metal, ceramic (ZrO2) or silicon carbide (SiSiC).

- Millbase separation by dynamic gap

- Mechanical shaft seal

- Seal pressure system with integrated cooling

- Minimised dead volume

- Dispersion of small quantities of millbase is possible due to almost complete product recovery

- Very high millbase yield

- Excellent temperature transfer due to guided cooling water system with extremely large surface area

- Easy to use and secure to handle

- Quick change of millbase due to particularly easy and simple cleaning

- Single pass and continuous procedure

- Circulation milling with integrated pumping and stirring system

- Dispersion of flowing and non‒flowing products

- High mechanical power input permits processing of difficult to disperse materials

Highlights DISPERMAT® SL-C bead mill

<p>SPEED ADJUSTMENT<br /> with rotary pulse encoder</p>

<p>PROCESS CONTROL<br /> repeatable dispersion results</p>

<p>MILLING SYSTEM<br /> made of ZrO2 or SiSiC</p>

<p>SOFTWARE<br /> documentation, research and QA</p>

<p>SINCE 1972<br /> quality, precision & durable technology</p>

Features

| DISPERMAT® | Power | Speed | Milling chamber volume | Product volume |

|---|---|---|---|---|

| DISPERMAT® SL5-C bead mill | 1.1 kW | 0 – 6000 rpm | 0.05 liter 1.7 oz | 0.05 – 0.75 liter 1.7 – 25.4 oz |

| DISPERMAT® SL12-C bead mill | 1.1 kW | 0 – 6000 rpm | 0.125 liter 4.2 oz | 0.15 – 0.75 liter 5.1 – 25.4 oz |

| DISPERMAT® SL25-C bead mill | 2.2 kW | 0 – 6000 rpm | 0.25 liter 8.5 oz | 0.3 – 2.5 liters 10.1 oz – 2.6 qt |

| DISPERMAT® SL50-C bead mill | 3 kW | 0 – 6000 rpm | 0.5 liter 16.9 oz | 0.5 – 10 liters 16.9 oz – 2.6 gallons |

| DISPERMAT® SL100-C bead mill | 3 kW | 0 – 3000 rpm | 1 liter 1.1 qt | 1 – 20 liters 1.1 qt – 5.3 gallons |

| DISPERMAT® SL200-C bead mill | 4 kW | 0 – 3000 rpm | 2 liters 2.1 qt | 2 – 50 liters 2.1 qt – 13 gallons |

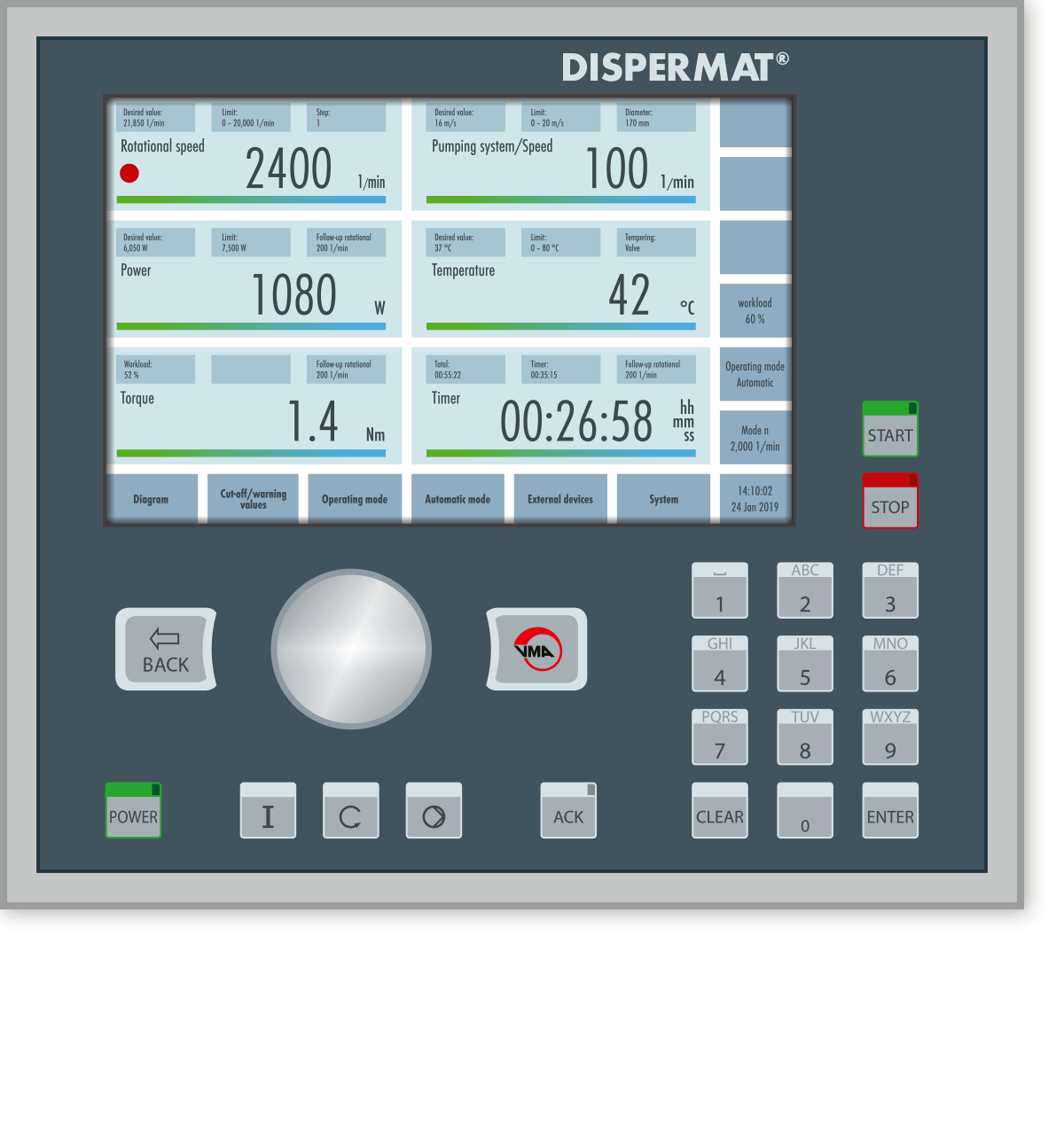

Process control

The DISPERMAT® SL-C bead mill is fitted with the C technology

C technology

DISPERWHEEL® speed adjustment

infinitely variable speed adjustment with rotary pulse encoder

Large color display

indications of speed, torque, power, product temperature, timer and peripheral speed

Repeatability

dispersion method: constant speed or constant mechanical power input for optimum repeatability, temperature‒based dispersing

Data recording

recording of the process parameters with graphical indication

Switch off parameters

switch off function for temperature, speed, torque and power

Database 100 individual PRESET configurations for speed, time, switch off parameters, ramp function, etc.

Power compensation

net power calibration

Connectivity

USB (Wi-Fi, LAN expected in 2022)

WINDISP 7©

data interface for WINDISP© 7 software for documentation, analysis, research, development and quality control