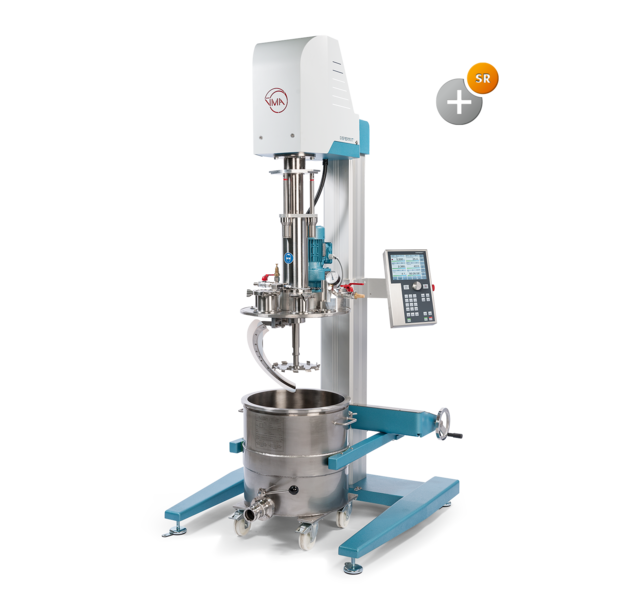

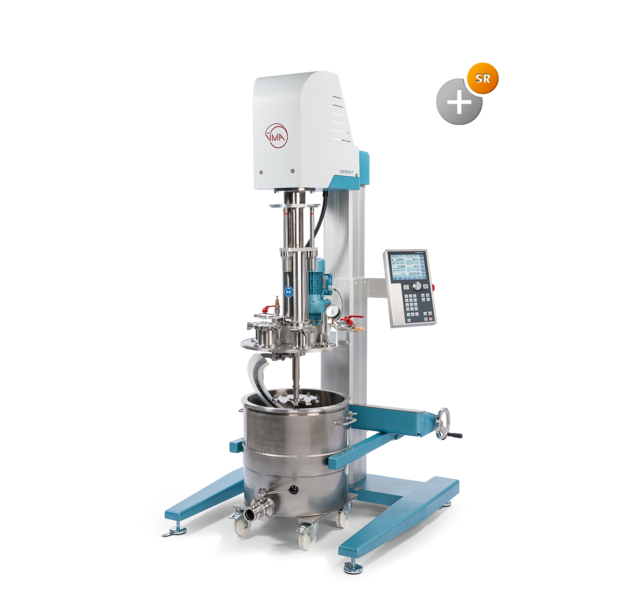

DISPERMAT® VL vacuum dissolver

Dispersion under vacuum with single and double‒walled vacuum containers

- Power

- 2.2 - 7.5 kW

- Product

- 4 - 80 litres

- Control

- C [Comfort]

Description

DISPERMAT® VL vacuum disperser with single‒walled or double‒walled vacuum containers from 1 to 100 litres

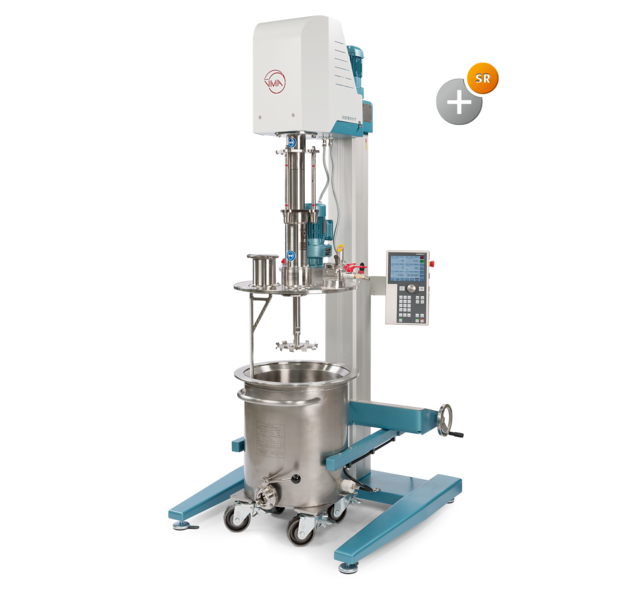

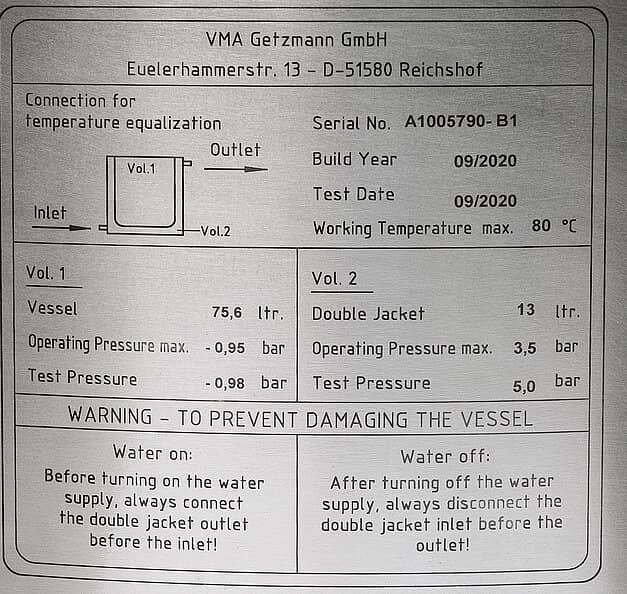

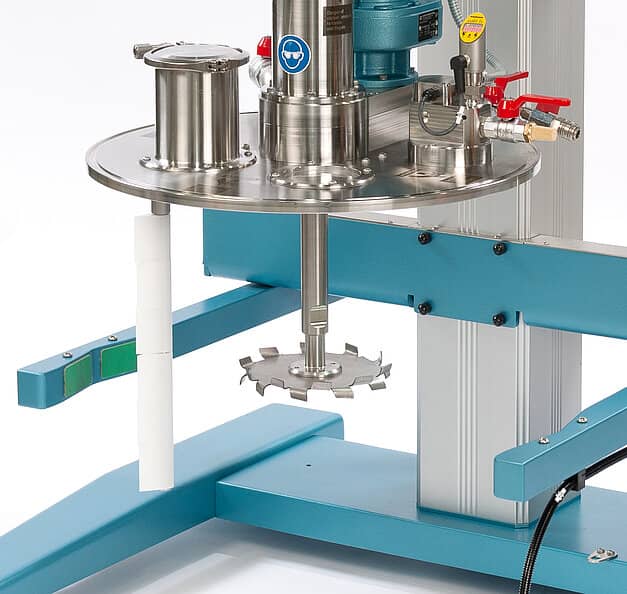

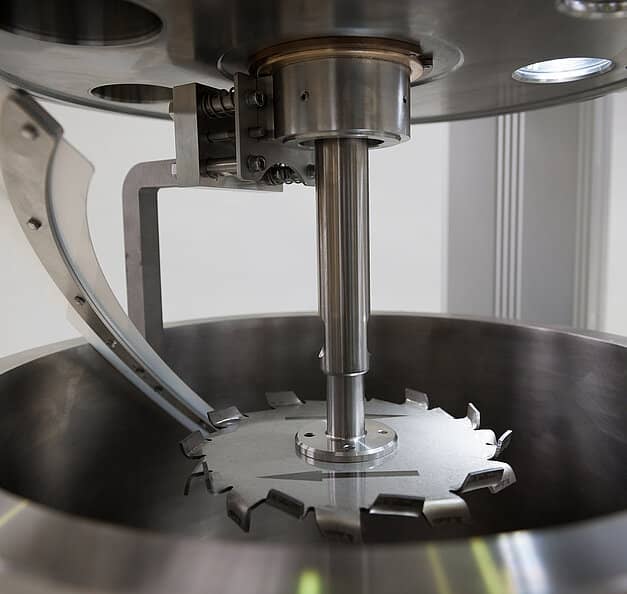

The DISPERMAT® VL is a vacuum dissolver for laboratory and pilot plant operation. It is ideal for R&D work as well as for production of larger batches. The DISPERMAT® VL is very easy to use. The stand has an electric height adjustment; the vacuum container is securely mounted on the base plate by a quick release fixture. The height of the milling tool can be adjusted during the dispersion process. The DISPERMAT® VL is also available in an explosion‒proof version according to ATEX. The single and double wall temperature‒controlled vacuum containers are made of stainless steel. A viewing glass, lamp, vacuum connection, filling opening and exhaust are all located in the stainless steel vacumm cover. The DISPERMAT® VL is also available with an optional scraper system.

Summary of the most important features:

- height adjustment of the dissolver disc even during vacuum operation

- stand with electric height adjustment

- double wall (temperature‒controlled) and single wall vacuum containers made of stainless steel

- vacuum cover with viewing glass, LED illumination, filling opening

- options: explosion‒proof (ATEX), scraper system, hopper

The high quality DISPERMAT® VL vacuum dispersers are suitable for many applications:

- Paints and varnishes

- Pigments and additives

- Printing inks

- Chemistry

- Plastics

- Construction chemistry

- Electronics

- Adhesives

- Coatings

- Pharmacy and cosmetics

- Microbiology

- Agrochemicals

Highlights DISPERMAT® VL vacuum dissolver

<p>MODULAR SYSTEMS<br /> Flexible. Powerful. Innovative.</p>

<p>DISPERMAT® TECHNOLOGY<br /> dispersing under vacuum</p>

<p>SPEED ADJUSTMENT<br /> with rotary pulse encoder</p>

<p>TÜV CERTIFIED<br /> Safety module (EN ISO 13849-1)</p>

<p>ELECTRIC<br /> easy handling, functional design</p>

<p>DIRECTIVE 2006/42/EC<br /> integrated safety equipment</p>

<p>ZONE 0/1/2<br /> explosion protection</p>

<p>SCRAPING SYSTEM<br /> for highly viscous products</p>

<p>DISPERMAT® TECHNOLOGY<br /> dispersing highly viscous substances</p>

<p>PROCESS CONTROL<br /> repeatable dispersion results</p>

<p>SOFTWARE<br /> documentation, research and QA</p>

<p>SINCE 1972<br /> quality, precision & durable technology</p>

Features

| DISPERMAT® | Power | Speed | Torque | Container | Product | Stand |

|---|---|---|---|---|---|---|

| DISPERMAT® VL1-5 | 2.2 kW | 0 – 6000 rpm | 7.4 Nm | 1 liter 1.1 qt | 0.3 – 0.7 liters 10.1 – 23.7 oz | H2L |

| DISPERMAT® VL1-5 | 2.2 kW | 0 – 6000 rpm | 7.4 Nm | 2 liters 2.1 qt | 0.5 – 1.5 liters 16.9 oz – 1.6 qt | H2L |

| DISPERMAT® VL1-5 | 2.2 kW | 0 – 6000 rpm | 7.4 Nm | 3 liters 3.2 qt | 0.8 – 2.2 liters 27.1 oz – 2.3 qt | H2L |

| DISPERMAT® VL1-5 | 2.2 kW | 0 – 6000 rpm | 7.4 Nm | 5 liters 1.3 gallons | 1.5 – 4 liters 1.6 qt – 1.1 gallons | H2L |

| DISPERMAT® VL10-35 | 4 kW | 0 – 3000 rpm | 27 Nm | 10 liters 2.6 gallons | 4 – 7 liters 1.1 – 1.8 gallons | H2SF |

| DISPERMAT® VL10-35 | 4 kW | 0 – 3000 rpm | 27 Nm | 15 liters 4 gallons | 5 – 12 liters 1.3 – 3.2 gallons | H2SF |

| DISPERMAT® VL10-35 | 4 kW | 0 – 3000 rpm | 27 Nm | 25 liters 6.6 gallons | 10 – 20 liters 2.6 – 5.3 gallons | H2SF |

| DISPERMAT® VL10-35 | 4 kW | 0 – 3000 rpm | 27 Nm | 35 liters 9.2 gallons | 10 – 25 liters 2.6 – 6.6 gallons | H2SF |

| DISPERMAT® VL50-100 | 7.5 kW | 0 – 3000 rpm | 50 Nm | 50 liters 13 gallons | 15 – 35 liters 4 – 9.2 gallons | H3S |

| DISPERMAT® VL50-100 | 7.5 kW | 0 – 3000 rpm | 50 Nm | 75 liters 20 gallons | 30 – 60 liters 7.9 – 16 gallons | H3S |

| DISPERMAT® VL50-100 | 7.5 kW | 0 – 3000 rpm | 50 Nm | 100 liters 26 gallons | 40 – 80 liters 10.6 – 21 gallons | H3S |

| DISPERMAT® VL1-5 Stand H2L | DISPERMAT® VL10-35 Stand H2SF | DISPERMAT® VL50-100 Stand H3S | |

|---|---|---|---|

| Dimensions W x H x D | 70 x 142 x 55 cm 27.6 x 55.9 x 21.7 inch | 90 x 210 x 70 cm 35.4 x 82.7 x 27.6 inch | 120 x 237 x 105 cm 47.2 x 93.3 x 41.3 inch |

| Height adjustment | electric | electric | electric |

| Weigh | 87 ‒ 101 kg 179 ‒ 223 lbs | 190 kg 419 lbs | 350 kg 772 lbs |

Process control

The vacuum dissolver DISPERMAT® VL is fitted with the C technology

C technology

DISPERWHEEL® speed adjustment

infinitely variable speed adjustment with rotary pulse encoder

Large color display

indications of speed, torque, power, product temperature, timer, peripheral speed and height of the dispersing tool

Repeatability

dispersion method: constant speed or constant mechanical power input for optimum repeatability, temperature‒based dispersing

Data recording

recording of the process parameters with graphical indication

Switch off parameters

switch off function for temperature, speed, torque and power

Database

100 individual PRESET configurations for H1, H2, speed, time, switch off parameters, ramp function, etc.

DISPERSAFE®

TÜV-certified safety module for convenient use of variable container sizes without limit switches or mechanical contraption. more …

Power compensation

net power calibration

Height measurement

adjustable working range for different container sizes

Connectivity

USB

WINDISP 7©

data interface for WINDISP© 7 software for documentation, analysis, research, development and quality control

Adaptable systems

Flexible. Powerful. Innovative.

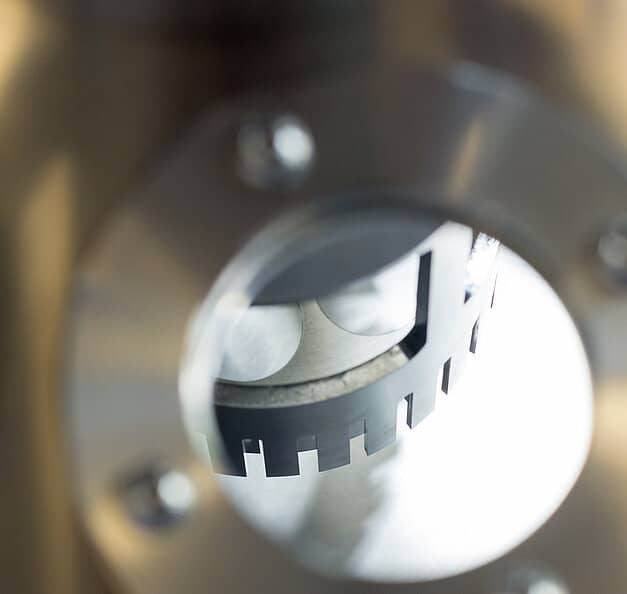

Innovation made in Germany: With the modular quick-change systems, the DISPERMAT® VL vacuum dissolver can also be used as: SR Rotor-Stator Homogenizer .

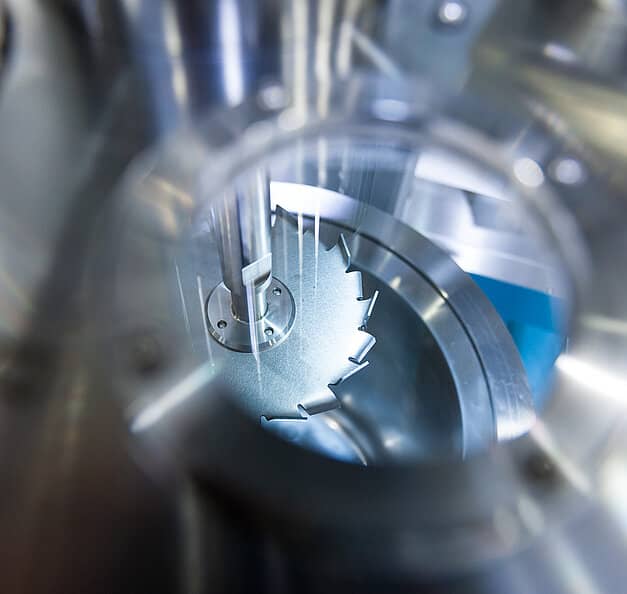

SR Rotor-Stator Homogenizer

Modular rotor-stator dispersion system

Vertical high-performance rotor-stator systems for homogenizing, emulsifying, dispersing, mixing and dissolving.

SR Rotor-Stator Homogenizer