Ceramic Inkjet

Ceramic inks are mainly used in tile printing. A small particle size of less than one micrometer is important in every case, without exception. This is the only way to prevent the pressure nozzles from being clogged. An efficient and effective dispersing process is of the highest priority. A stable dispersion is also required. If color pigments were to be re-agglomerated, this would have a major impact on the printing and baking process.

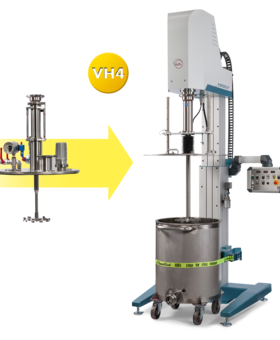

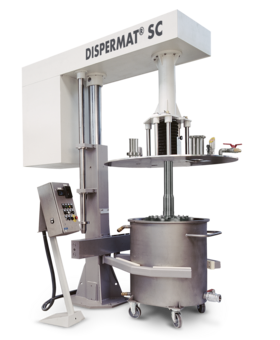

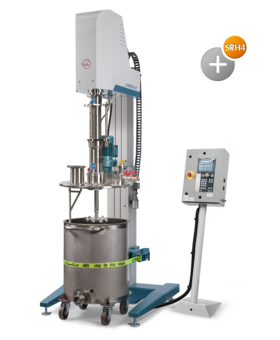

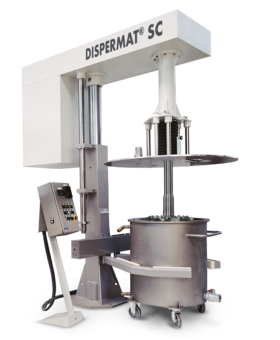

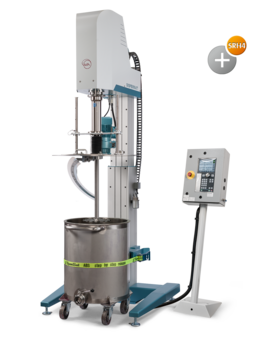

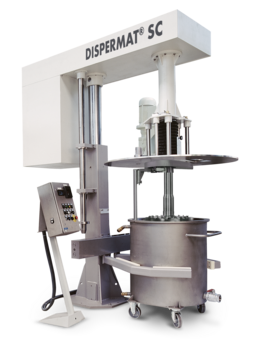

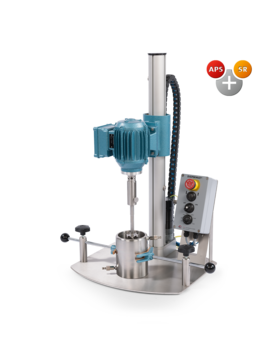

The DISPERMAT® dispersion devices of VMA-Getzmann support the dispersion and grinding process of ceramic inks with consistent results and therefore ensure a consistently stable quality of printing.