Special paints for wind turbines

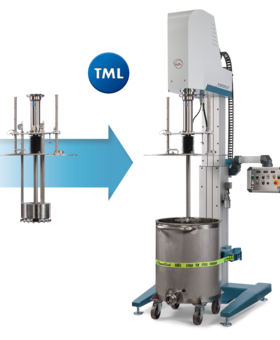

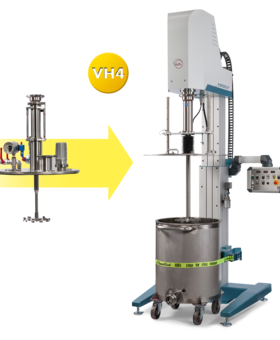

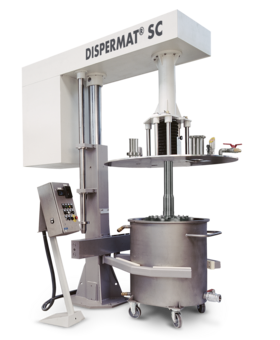

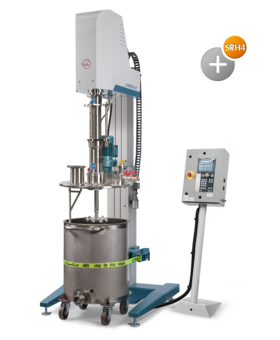

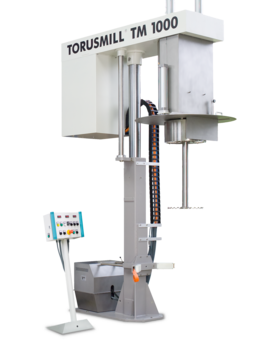

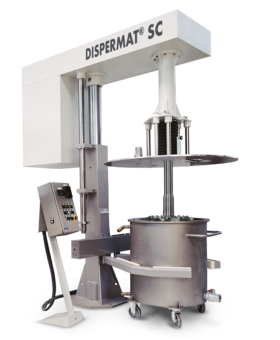

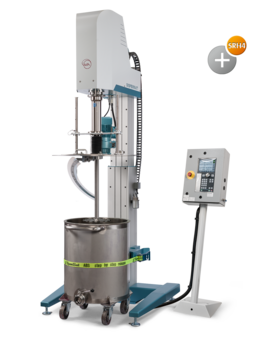

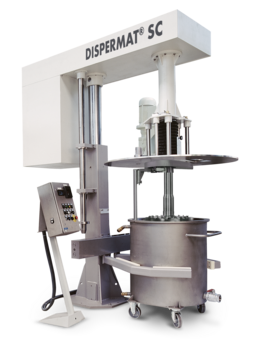

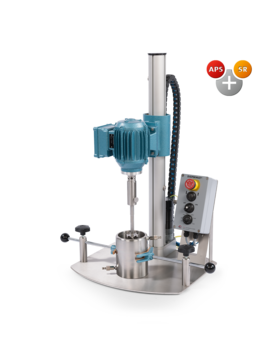

Depending on their location, wind turbines are exposed to strong weather conditions all year round, even to aggressive sea air. In addition to these great challenges for paints, wind turbines also have to resist insects. Indeed, any contamination on the surface of rotor blades has a negative influence on flow properties. Self-cleaning coatings are also required here. The requirements for such coatings are special and complex. VMA-Getzmann offers a complete range of DISPERMAT® laboratory, dispersion and grinding devices. With these devices, the desired properties can be optimally developed in order to reproduce them on a production scale.