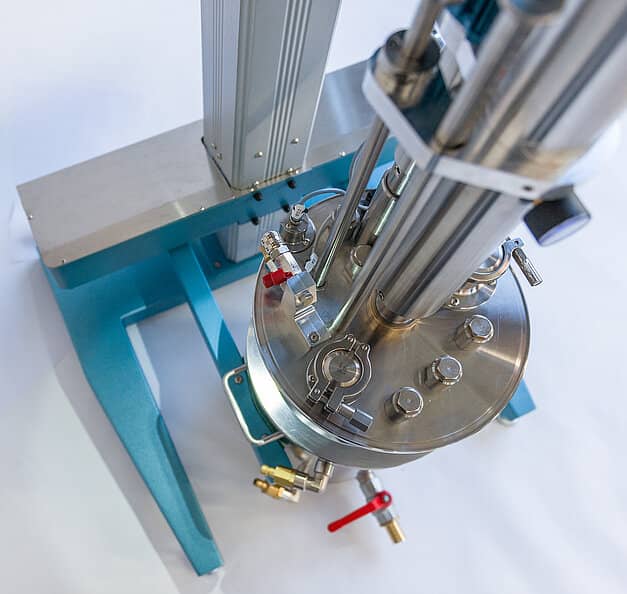

DISPERMAT® LH vacuum dissolver

Twin shaft disperser and butterfly stirrer for dispersing high‒viscosity or non‒flowing substances under vacuum.

- Power

- 3 - 4 kW

- Product

- 4 - 14 litres

- Control

- C [Comfort]

The DISPERMAT® LH vacuum dispersion system consists of a high‒speed laboratory disperser and an integrated three blade butterfly stirrer. Through the interaction of the two dispersion processes, substances more

Description

DISPERMAT® LH vacuum dissolver for high‒viscosity product volumes from 4 to 14 litres.Option: explosion‒protection according to ATEX

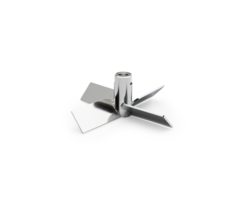

The DISPERMAT® LH vacuum dispersion system consists of a high‒speed laboratory disperser and an integrated three blade butterfly stirrer. Through the interaction of the two dispersion processes, substances with high‒viscosity and higher yield point can be mixed. Powder products can also be dispersed into highly viscous and non‒flowing substances. Precisely engineered dispersion tools ensure that the entire substance is incorporated into the dispersion process.

WINDISP© 7

The optional WINDISP© 7 PC‒software can be used to record and log the experimental dispersion data. A bidirectional interface allows WINDISP© 7 to control certain functions of the dissolver, for example dispersing at a specific temperature by regulating the dissolver speed. Additional functions include curve overlay for data comparison, event marker, a data base and data export to EXCEL.

Highlights DISPERMAT® LH vacuum dissolver

<p>DISPERMAT® TECHNOLOGY<br /> dispersing under vacuum</p>

<p>DISPERMAT® TECHNOLOGY<br /> dispersing highly viscous substances</p>

<p>SPEED ADJUSTMENT<br /> with rotary pulse encoder</p>

<p>TÜV CERTIFIED<br /> Safety module (EN ISO 13849-1)</p>

<p>ELECTRIC<br /> easy handling, functional design</p>

<p>DIRECTIVE 2006/42/EC<br /> integrated safety equipment</p>

<p>PROCESS CONTROL<br /> repeatable dispersion results</p>

<p>ZONE 0/1/2<br /> explosion protection</p>

<p>SOFTWARE<br /> documentation, research and QA</p>

<p>SINCE 1972<br /> quality, precision & durable technology</p>

Features

Process control

The vacuum dissolver DISPERMAT® LH is fitted with the C technology

C technology

DISPERWHEEL® speed adjustment

infinitely variable speed adjustment with rotary pulse encoder

Large color display

indications of speed, torque, power, product temperature, timer, peripheral speed and height of the dispersing tool

Repeatability

dispersion method: constant speed or constant mechanical power input for optimum repeatability, temperature‒based dispersing

Data recording

recording of the process parameters with graphical indication

Switch off parameters

switch off function for temperature, speed, torque and power

Database

100 individual PRESET configurations for H1, H2, speed, time, switch off parameters, ramp function, etc.

DISPERSAFE®

TÜV-certified safety module for convenient use of variable container sizes without limit switches or mechanical contraption. more …

Power compensation

net power calibration

Height measurement

adjustable working range for different container sizes

Connectivity

USB

WINDISP 7©

data interface for WINDISP© 7 software for documentation, analysis, research, development and quality control