Dispersion process

The dispersion process: wetting, mechanical size reduction, product stabilisation

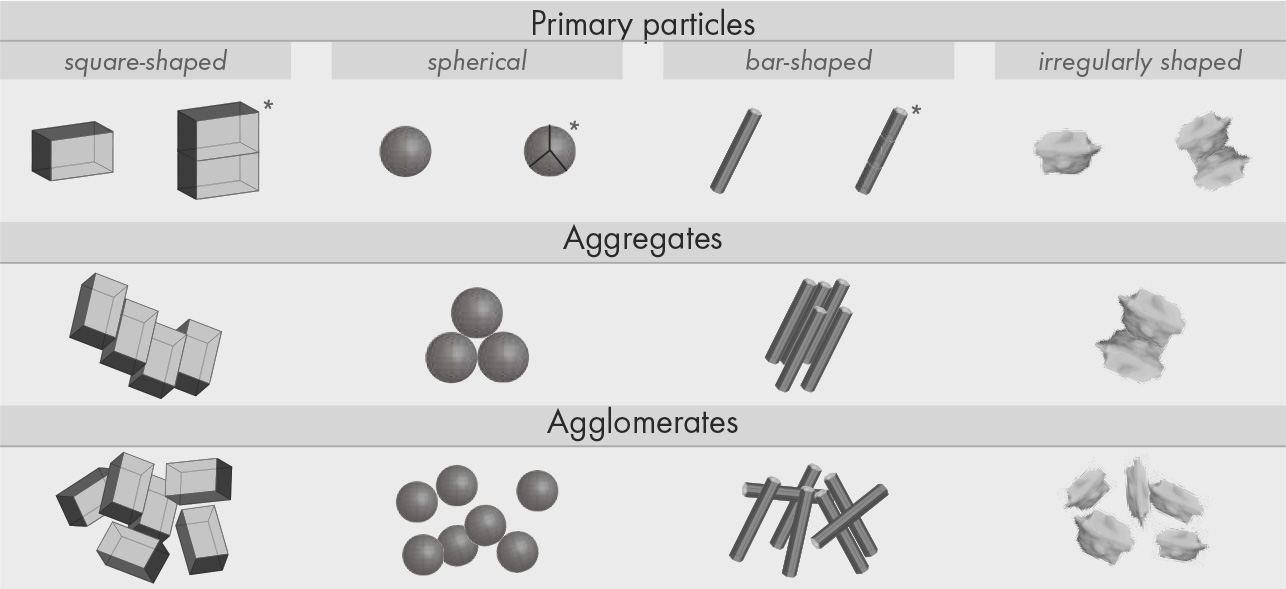

The most frequent application of high‒speed dispersion is to incorporate extremely fine solid particles into fluids, to produce colloidal suspensions. Colloidal suspensions are characterised by their behaviour that the finely divided small particles do not settle under the force of gravity. A sequence of related steps take place during the dispersing process. These are:

- the wetting of the surface of the solid particles by the fluid components of the millbase

- the mechanical breakdown of associated particles leading to smaller particles (agglomerates and aggregates)

- the smaller particles generated during the dispersion are stabilised, preventing renewed association (flocculation)

Special interaction between the solid particles and the fluid components of the millbase determine their wetting and resistance to flocculation.

25. - 27.03.2025

ECS 2025

Hall 4 / Booth 4-114

Nuremberg, Germany

Experience our dispersion technology! Know-how and top quality since 1972.

At our trade fairs, we present our latest innovations as well as a representative exhibition of patented dispersing and fine grinding systems DISPERMAT® and TORUSMILL®.