Cosmetics & body care

Natural pigments, fats and oils are often used in the cosmetics industry. The manufacturing process is subject to strict requirements. When dispersing and grinding, the challenge is in ensuring a stable dispersion with homogeneous properties and very fine particles. Coarse particles would negatively affect the feel of some cosmetics, as they can be perceived as annoying on the skin.

Another challenge is in producing the consistent quality of the final product. A newly developed C-control unit of VMA-Getzmann offers complete data control and acquisition during the dispersion and grinding process. In this way, processes can be better evaluated and reproduced.

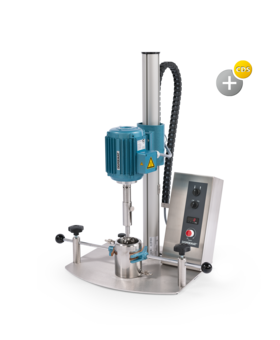

Whether you need explosion protection (according to ATEX), special materials (with material certificates) or particularly smooth surfaces (Ra <0.4 µm), VMA-Getzmann offers tailor-made solutions with the DISPERMAT® range to make the process efficient.