Dispersion process under vacuum

During the dispersion process air is often trapped in the millbase. If the millbase viscosity is low enough the air will often escape naturally by itself during or after the dispersion process. The use of anti‒foam additives can also help. In industry today it is a requirement of many dispersed products to be free of air bubbles. Trapped air affects filling and end product performance and can be a serious problem. In these cases vacuum can be used to eliminate or to reduce the amount of trapped air in higher viscosity products.

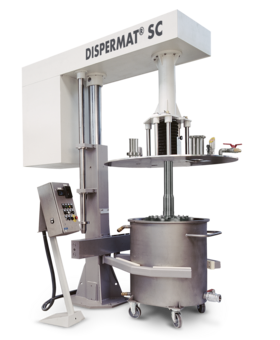

Then, the dispersion process must be performed under vacuum to avoid air inclusions and micro bubbles. In addition, the use of a scraping system is often required to move the millbase from the container wall and bring it to the middle of the container. The improved product circulation allows the air to be removed more effectively.

Major advantages of a dispersion under vacuum:

- high‒viscosity systems can largely be produced without air bubbles

- a formation of foam is largely reduced especially in the case of aqueous system

- products which react with oxygen or air humidity can be produced under vacuum without any problems

- the product quality (fineness) can often be improved significantly by vacuum dispersion

Do you want to know more about the advantages of dispersions under vacuum? We should be pleased to advise you! Please visit us in our excellently equipped laboratory and pilot plant for a trial with your own products. Our experienced engineers are looking forward to your visit.

Trade fairs

BRAZIL

23. - 25.09.2025

ABRAFATI, Sao Paulo

USA

06. - 09.10.2025

THE BATTERY SHOW, Detroit

ITALY

08. - 09.10.2025

PAINT & COATINGS, Milano

INDONESIA

29. - 31.10.2025

PACIFIC COATINGS, Jakarta

SPAIN

19. - 20.11.2025

PAINT & COATINGS, Barcelona

UAE

20. - 22.11.2025

GULF COATINGS SHOW, Sharjah

CHINA

25. - 27.11.2025

CHINA COAT, Shanghai

DISPERMAT® and TORUSMILL®

Durable and highly efficient dispersers, mixers, stirrers, basket mills and bead mills in operation worldwide

VMA‒GETZMANN develops, produces and markets high quality dispersers, mixers, stirrers, bead mills and basket mills. The innovative combination of technology and design as well as high quality are characteristic of our products. Of course, our mixing, dispersing and grinding equipment have integrated safety devices according to the EC Machinery Directive 2006/42 / EC.

Working together with the client our specialists optimize the essential process engineering and the most suitable system solution. Our involved development and design team comes with innovative ideas and long time experience in the mixing, dispersing and grinding technology. We produce with the most modern machine tools and therefore we guarantee a high standard of quality. We prove our expertise and reliability by also having an excellent after sales service.

Our experience ‒ Your advantage

Please visit us in our excellently equipped laboratory and pilot plant for a trial with your own products. We would be pleased to show you the impressive work section of our dispersing, mixing, stirring, homogenizing and fine grinding systems DISPERMAT® and TORUSMILL®. Our skilled engineers are available at any time for personal advice.