Screen printing inks

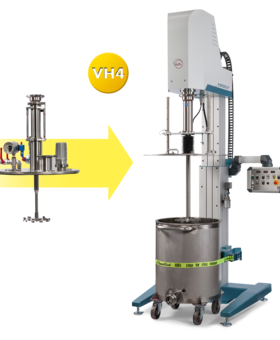

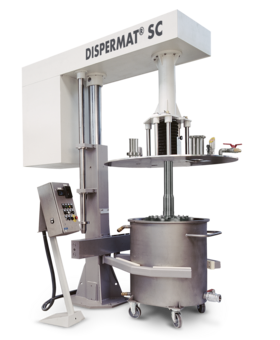

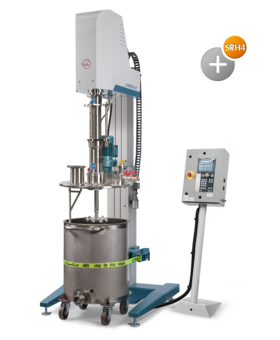

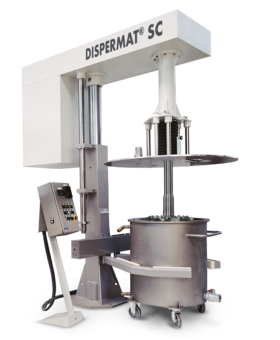

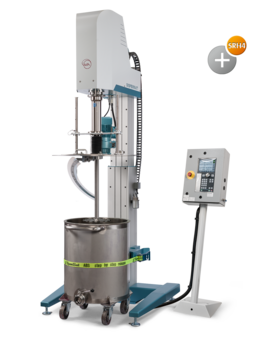

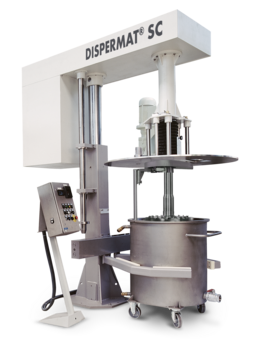

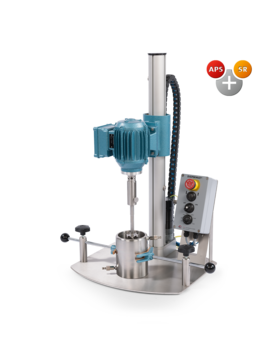

The DISPERMAT® dissolver and agitator ball mills are ideally suited for the production of high-quality screen printing inks. With both systems, color pigments can be pre-dispersed and then ground. After setting the optimal viscosity, screen printing inks are applied to various carrier media with a layer thickness of up to 15 µm.