TORUSMILL® TM537 basket mill

2 in 1: patented basket mill with integrated dissolver for containers up to 1250 liters

- Power

- 37 kW

- Product

- 100 – 1000 litres

- Control

- TM / C / PLC

The TORUSMILL® TM537 is a patented dispersion system which allows for a particularly economic and environmental dispersion of high quality products. With the TORUSMILL® TM537 a predispersion with a dissolver more

Description

SAVE TIME: Highly efficient combination of dissolver and basket mill. Dispersing and fine grinding with one machine. Option: ATEX Zone 0/1/2, vacuum design, PLC-control, ceramic version, scraper system

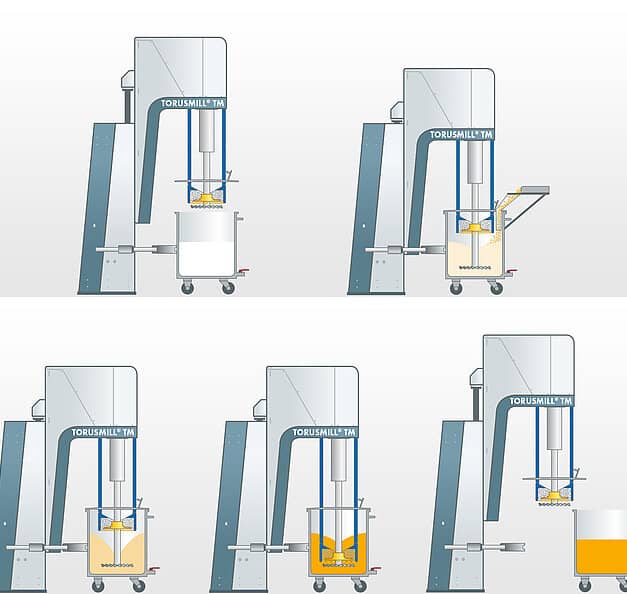

The TORUSMILL® TM537 is a patented dispersion system which allows for a particularly economic and environmental dispersion of high quality products. With the TORUSMILL® TM537 a predispersion with a dissolver disc and afterwards the extremely fine grinding with an integrated basket mill can be made in one process and one container. This innovation intelligently combines proven high speed dispersion technology with a basket mill system. In operation, the TORUSMILL® TM537 is first used to predisperse the product with a dissolver disc. During predispersion the torus shaped basket is "parked" in the upper part of the machine. After predispersion the milling basket containing the milling beads and the milling tool is lowered into the mill base and the fine milling process can begin. The fast circulation of the millbase within the milling basket is generated by the dissolver disc and integrated pump wheel; because of this excellent dispersion results and a very narrow particle size distribution can be achieved very quickly. Due to the fact that no pumps, pipes, valves and additional containers are necessary, the cleaning is very easy and a quick change of the millbase is possible.

High quality. Long–lasting. Practical. The patented dispersion system TORUSMILL® TM537:

- Predispersion and fine grinding in a closed system

- Particularly robust and functional design

- High circulation rates even with highly viscous products due to the patented pump wheel

- Excellent milling results in a very short time as well as a narrow particle size distribution

- Easy scale–up from the laboratory system TML to the production machine TM

- Customers can use their own containers

- Temperature regulation due to double walled milling basket with restraint-guided cooling system

- Space‒saving: 2 procedures – 1 machine

- System related easy to clean allowing for quick product changes

The TORUSMILL® TM537 production basket mill has an integrated cover:

The stable cover of the TORUSMILL® TM537 immersion mill enables easy height adjustment of the shaft even during the fine grinding process. The cover rests securely on the container edge during the grinding process. The cover is equipped with a product feed system as a standard. Various options, such as LED lighting, a PT100 temperature sensor, a Liquiphant level switch (also in ATEX), or sight glasses and various filling funnels are available for the container cover.

For vacuum operation or for solvent based products using of a completely closed cover is essential. A suitable vacuum container is required for the dispersion process under vacuum.

The TORUSMILL® TM537 production immersion mill is equipped with the BK5 stand:

The elegant stand of the TORUSMILL® TM537 series has an integrated, electrical height adjustment. This new intelligent and particularly robust design was developed with a focus on purely functional and economic aspects, and features the innovative nature of the TORUSMILL® technology.

Highlights TORUSMILL® TM537 basket mill

<p>ELECTRIC<br /> easy handling, functional design</p>

<p>DIRECTIVE 2006/42/EC<br /> integrated safety equipment</p>

<p>ZONE 0/1/2<br /> explosion protection</p>

<p>TORUSMILL® TECHNOLOGIE<br /> fine grinding under vacuum</p>

<p>SCRAPING SYSTEM<br /> for highly viscous products</p>

<p>TORUSMILL® TECHNOLOGY<br /> fine grinding of highly viscous media</p>

<p>FINE GRINDING<br /> down to the nano scale</p>

<p>PROCESS CONTROL<br /> repeatable dispersion results</p>

<p>SPEED ADJUSTMENT<br /> with rotary pulse encoder</p>

<p>TÜV CERTIFIED<br /> Safety module (EN ISO 13849-1)</p>

<p>SOFTWARE<br /> documentation, research and QA</p>

<p>SINCE 1972<br /> quality, precision & durable technology</p>

Features

Process control

The TORUSMILL® TM537 production basket mill can be equipped with various control technologies.

C technology

DISPERWHEEL® speed adjustment

infinitely variable speed adjustment with rotary pulse encoder

Large color display

indications of speed, torque, power, product temperature, timer, peripheral speed and height of the dispersing tool

Repeatability

dispersion method: constant speed or constant mechanical power input for optimum repeatability, temperature‒based dispersing

Data recording

recording of the process parameters with graphical indication

Switch off parameters

switch off function for temperature, speed, torque and power

Database

100 individual PRESET configurations for H1, H2, speed, time, switch off parameters, ramp function, etc.

DISPERSAFE®

TÜV-certified safety module for convenient use of variable container sizes without limit switches or mechanical contraption. more …

Power compensation

net power calibration

Height measurement

adjustable working range for different container sizes

Connectivity

USB

WINDISP 7©

data interface for WINDISP© 7 software for documentation, analysis, research, development and quality control

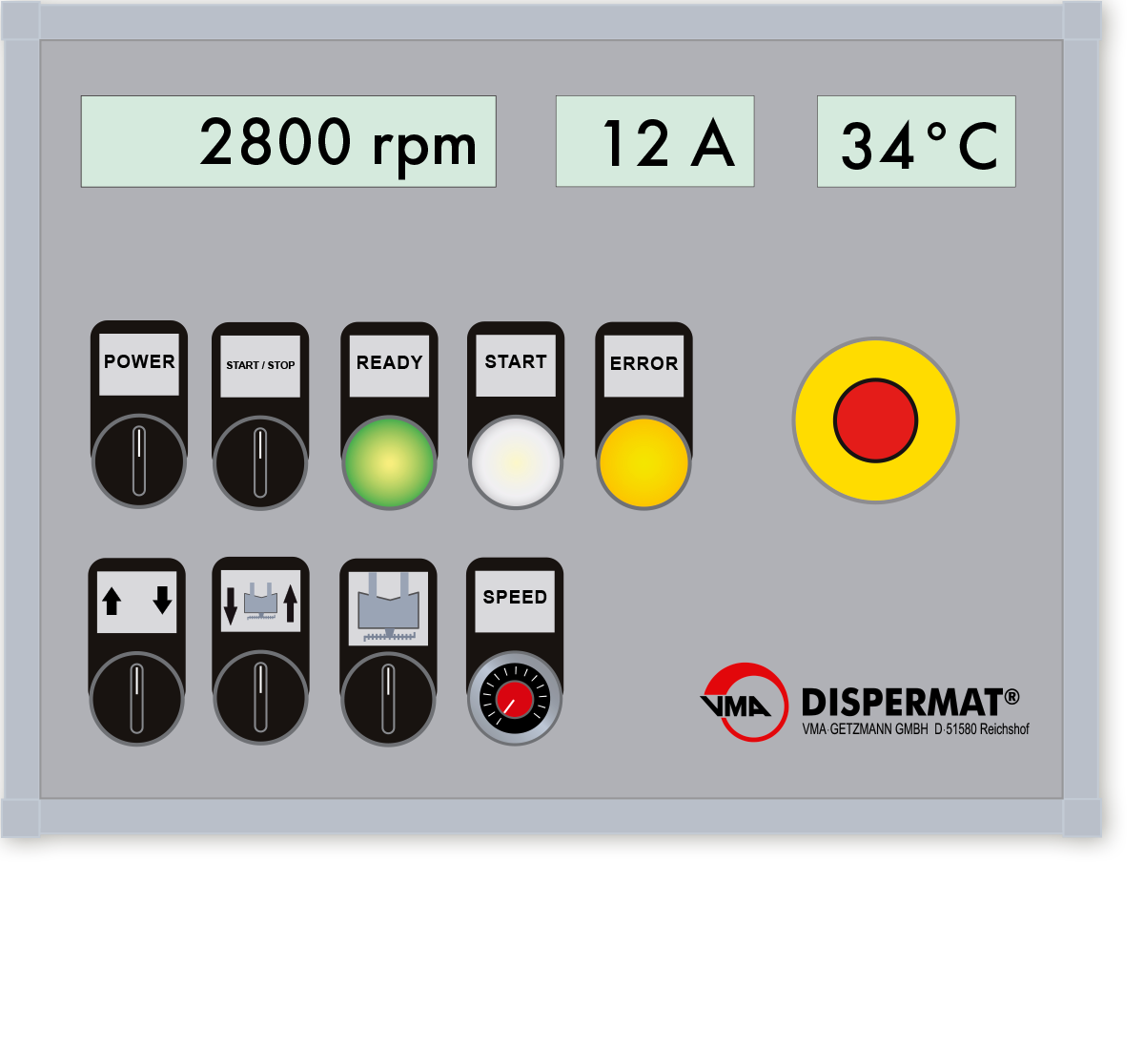

TM technology

Speed adjustment:

infinitely variable speed adjustment

Digital indication:

for speed, ampere and product temperature (as an option)

Height adjustment:

convenient height adjustment for the drive motor, separate height adjustment of the stand, dissolver disc and basket

Drain off grinding basket:

control element for emptying the grinding basket

Operator controls:

for power, start, stop and emergency stop

PLC technology

The DISPERMAT® and TORUSMILL® dissolvers, bead mills and basket mills can also be fitted with the PLC-control. The graphic display allows for an indication of the operational parameters such as speed, power output, peripheral speed of the milling tool, torque and product temperature. The combination of a graphic display and the standardized PLC-control allows for an extension as well as for an adaptation of the control system to further process control applications at any time.